What materials are suitable for compost turning with a rotary compost turner?

Compost turners are suitable for composting a variety of organic wastes, such as livestock and poultry manure (chicken, cow, and pig manure), sewage sludge, sugar factory filter mud, lees, cakes, and straw sawdust. These materials are rich in organic matter, and a rotary compost turner can accelerate their fermentation and composting, transforming them into high-quality organic fertilizer. For example, large-scale livestock and poultry farms, which produce large quantities of livestock and poultry manure, can use a rotary compost turner to process the waste, realizing resource utilization.

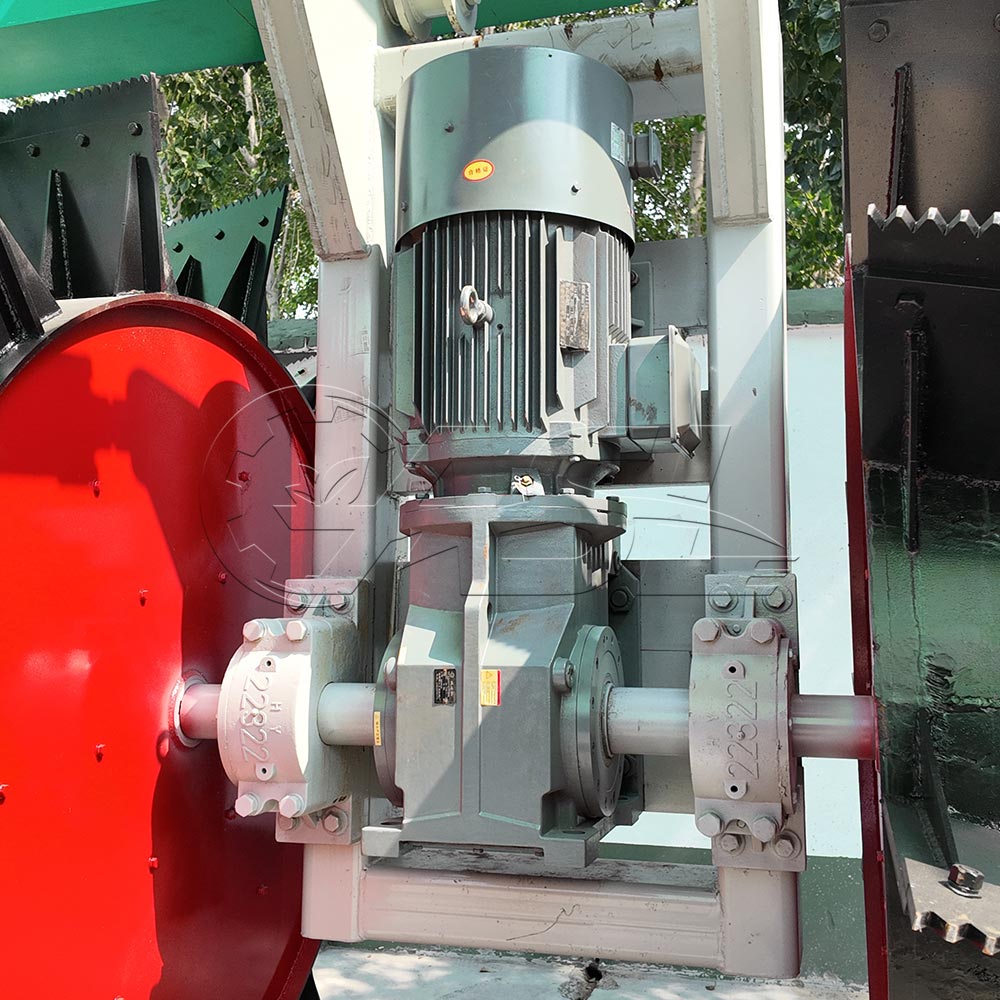

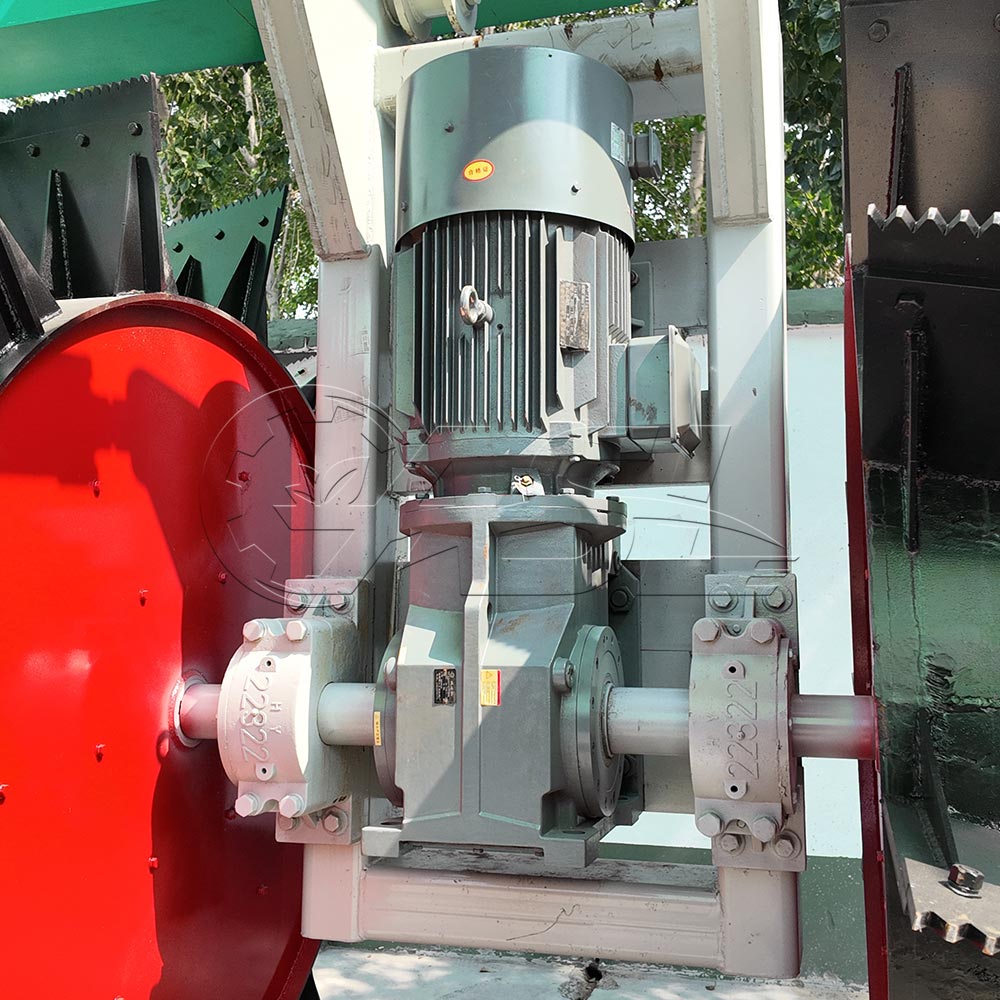

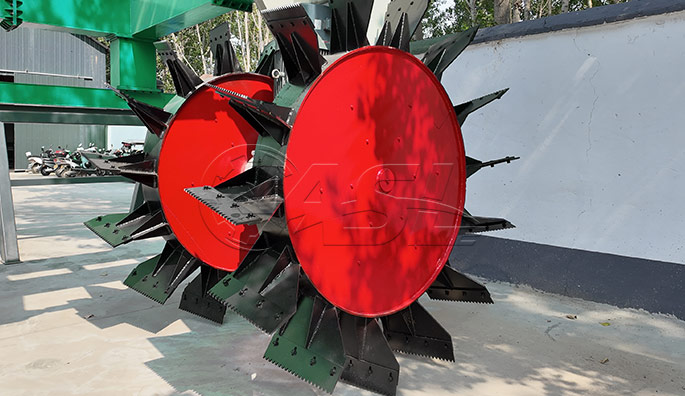

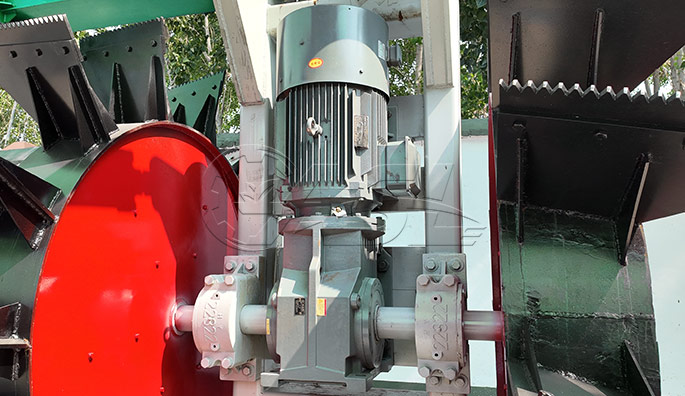

What are the advantages of a disc-type compost turner compared to other types of compost turners?

1. Compared to trough-type compost turners, disc-type compost turners require less space and do not require dedicated fermentation tanks. They can operate flexibly in more open areas, saving the cost and space of building fermentation tanks.

2. Compared to walking compost turners, they offer greater turning force and a wider range, making them particularly suitable for handling large, deep piles.

For example, in large organic fertilizer production plants, faced with large piles of material, disc-type compost turners, with their large span and deep turning capabilities, can more efficiently and evenly turn the material, thereby improving the fermentation quality of the organic fertilizer.

How do I choose the right compost turner model for my needs?

1. First, consider the material handling capacity. For small farms or plantations with limited material production, a smaller compost turner with a smaller handling capacity can be selected. Large-scale organic fertilizer production enterprises, however, with large material handling volumes, require larger, more efficient equipment.

2. Secondly, consider site conditions. If the site is open and irregular, the flexible operation of a compost turner is ideal. If the site is relatively cramped, choose a model that is appropriately sized and does not take up too much space.

3. Furthermore, material characteristics are crucial. For example, if the material is highly viscous, a machine with a strong turning force and wear-resistant blades will be required. If the material is fluffy, the turning force requirement can be reduced.

Is a wheel compost turner complicated to operate? Does it require professional assistance?

Rotary compost turners are not very complex to operate. Most machines are equipped with a fully automated electrical control system, allowing for both manual and automatic control. In automatic mode, the operator simply sets the relevant parameters (such as turning depth and travel speed), and the machine automatically operates according to the program. In manual mode, the operator uses a central control cabinet to operate the machine, controlling various buttons to control forward, horizontal, turning, and reverse operations. Generally speaking, after simple training, ordinary workers can become proficient in operating the machine. However, professional guidance or repair may be required for first-time use or when the machine malfunctions.