Spiral solid-liquid separator Structure:

Main shaft and spiral blades: The core power components. The spiral blades are welded to the main shaft and feature a tapered or variable-pitch design (the pitch gradually decreases and the diameter gradually increases from the feed end to the discharge end). Rotation generates axial thrust, conveying the material forward while simultaneously applying extrusion pressure to the material through spatial compression, forcing moisture out.

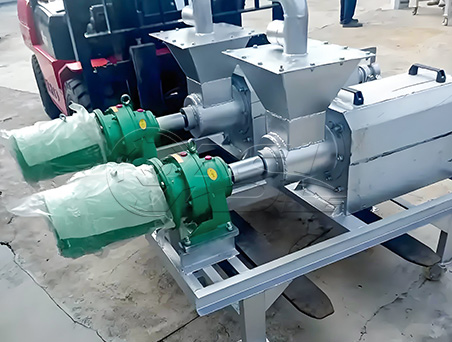

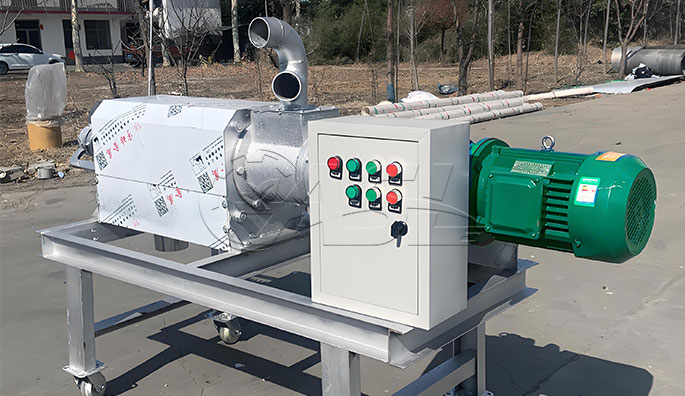

Drive: Consisting of a motor and a reducer, they provide rotational power to the spiral shaft. The speed can be adjusted via a frequency converter to accommodate different material characteristics.

Screen: A cylindrical or conical filter fitted over the spiral blades, a key component in solid-liquid separation. Mostly made of stainless steel, it offers corrosion and wear resistance. The mesh size can be customized based on the material particle size and separation requirements. During operation, the extruded liquid seeps through the mesh, while the solids are pushed toward the discharge port by the spiral.

Pressure regulating device: An adjustable tapered plug or baffle located at the discharge end of the spiral controls the discharge resistance by varying the gap between it and the end of the screen. The smaller the gap, the greater the extrusion pressure and the lower the moisture content of the solids. Drain Trough: A circular or semi-circular groove surrounding the outside of the screen collects liquid that seeps through the screen and drains it through a bottom pipe to the subsequent sewage treatment system.

Frame and Protective Cover: The frame is a steel structure that supports the entire equipment weight and ensures operational stability. The protective cover covers rotating components such as the screw and screen, preventing material splashing and operator contact, enhancing safety.

Overload Protection Device: Some models are equipped with a current overload protector or torque limiter. If the equipment load exceeds the set value due to material blockage or hard objects, the machine will automatically shut down or reverse, preventing damage to the motor, screw blades, and other components.

Application Areas

1. Agricultural Animal Husbandry: Used for livestock and poultry manure treatment, such as pig and cow manure, separating the manure mixture into liquid and solid organic fertilizer raw materials, reducing odor, and facilitating subsequent processing and utilization.

2. Food Processing: Dehydrating fruit and vegetable residues, distiller's grains, and bean curd residues to achieve resource recycling. For example, the dehydrated fruit and vegetable residues can be made into feed or used in the production of other products.

3. Municipal Environmental Protection: Dehydrating sludge in sewage treatment plants to reduce its moisture content, facilitating subsequent incineration or landfill, and achieving waste reduction.

4. Industrial Wastewater Treatment: Treating sediments such as heavy metal sludge and fiber residue in wastewater from industries like electroplating, printing and dyeing, and papermaking, achieving the goal of reducing hazardous waste and ensuring compliant disposal.

5. Food Waste Treatment: Pre-treating wet waste to reduce its moisture content, improving transportation efficiency and the feasibility of subsequent processing, such as for black soldier fly farming or composting.