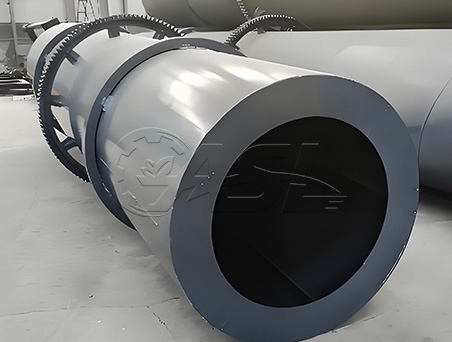

Rotating Drum: The main body is a cylindrical drum with an inclined angle (3-5°), typically made of stainless steel or carbon steel (with an anti-corrosion treatment on the interior wall). Some drums may be equipped with lifting plates or guide plates on the interior wall.

Drive System: Consists of a motor, reducer, and rollers (or gears), driving the drum at a low speed (5-15 rpm).

Coating Agent Dosing System: Includes a storage tank, metering pump (for liquid coating agents) or screw conveyor (for powder coating agents), and atomizing nozzle (for liquids only).

Support and Adjustment System: Consists of a base, roller assembly, and retaining rollers.

Auxiliary Systems: Some units are equipped with a hot air device (for rapid drying of liquid coating agents) and a dust collector (such as a pulse dust collector).

Application Areas

1. Commercial organic fertilizer: Coated with an anti-caking agent to address storage issues and increase market acceptance.

2. Slow-release organic fertilizer: Produces long-lasting fertilizer suitable for crops such as fruit trees and Chinese medicinal herbs that require a long-term fertilizer supply, reducing fertilization frequency.

3. Functional organic fertilizer: Produces biofertilizer and micronutrient fertilizer to ensure bacterial activity and nutrient effectiveness.

4. Organic-inorganic compound fertilizer: Balances the release of organic and inorganic nutrients to prevent inorganic nutrient loss and caking.

Working principle of the Rotary Coating Machine:

The main motor drives the belt and pulley, which is then transmitted to the drive shaft via a speed reducer. The split gears mounted on the drive shaft mesh with the large ring gear fixed to the machine body, working in opposite directions. Material is added at the feed end, passes through the interior of the cylinder, mixes with the powder (liquid), and flows out of the discharge port.

Advantages of Rotary Coating Machine:

1. Uniform Coating:

Adhesion rate exceeds 95%, with no leaking or over-thickness issues, ensuring consistent product quality.

2. High Adaptability:

It can process pellets ranging from 1-8mm, with a moisture content of ≤15%, adapting to a variety of organic fertilizer raw materials.

3. Low Breakage Rate:

Low-speed operation and a smooth interior ensure a pellet breakage rate of ≤1%, preserving pellet integrity.

4. Flexible Adjustability:

The speed, inclination angle, and coating agent dosage can be adjusted to meet various needs, including anti-caking and sustained-release.

Model | Motor Power(kw) | Reducer Model | Installation Tilt Angle(degree) | Rotary Speed(r/min) |

ASLHB-1240 | 5.5*2 | ZQ350 | 2-3 | 11 |

ASLHB-1560 | 5.5*2 | ZQ400 | 2-3 | 11 |

ASLHB-1870 | 7.5*2 | ZQ500 | 2-3 | 10 |

ASLHB-2080 | 11*2 | ZQ650 | 2-3 | 10 |

What is the core function of a rotary film coating machine for organic fertilizer? What production pain points can it address?

The core function of a rotary film coating machine for organic fertilizer is to evenly coat the surface of organic fertilizer granules with a functional film. The film material can be selected according to needs (such as anti-caking agents, slow-release agents, trace elements, water-retaining agents, etc.). It can address three major production pain points: First, it prevents the finished organic fertilizer from clumping due to moisture absorption during storage and transportation, ensuring the looseness of the granules. Second, by coating with a slow-release film, the fertilizer's nutrient release cycle is extended, improving the fertilizer's long-term effectiveness. Third, it reduces dust generated during application, minimizing nutrient loss and preventing soil and environmental pollution.

"How can the coating effect be ensured to be uniform?"

High-quality rotary film coating machines ensure coating uniformity through three key design features: First, they utilize an inclined rotary drum, which rotates as the granules within the drum, creating a "tumbling-sliding-tumbling" cycle, which circulates with the coating liquid. The first is to ensure full contact between the pellets and the powder; the second is to equip the drum with multiple atomizing nozzles to evenly spray (or spread) the coating agent onto the pellet surface; the third is to install a lifting plate inside the drum to lift the pellets upward and evenly distribute them to avoid localized accumulation.

What factors affect coating quality?

There are four key factors affecting coating quality: ① Coating agent concentration (a high concentration can cause pellets to stick together, while a low concentration can result in an incomplete coating layer); ② Drum speed (a high speed can cause coating agent splashing, while a slow speed can result in uneven mixing of the pellets); ③ Feed rate (must match the equipment's processing capacity; overloading can result in insufficient pellet residence time in the drum, resulting in incomplete coating); and ④ Particle humidity (high humidity can lead to poor coating agent adhesion and easy peeling of the coating layer).

What particle size of organic fertilizer pellets can the equipment process? Is there a requirement for pellet hardness?

The organic fertilizer rotary coating machine is highly adaptable to particle sizes, processing 0.5-8mm. Organic fertilizer granules include common forms such as conventional powdered organic fertilizer (which requires granulation), columnar organic fertilizer, and pelletized organic fertilizer.

Pellets have a basic hardness requirement: the compressive strength must be ≥2N to prevent breakage due to impact during tumbling. If the granules are not sufficiently hard (such as wet granules from fresh granulation), it is recommended to dry and cool them before coating them. This prevents broken granules from mixing with the coating agent and forming clumps, which could affect the final coating effect.

Copyright 2025 Henan Nonghuilian Machinery Co., Ltd. Sitemap