What materials are suitable for the new vertical grinder for organic fertilizer?

The new vertical grinder can be used for a wide range of organic materials, including livestock and poultry manure (chicken manure, cow manure, pig manure, etc.), crop straw (corn straw, wheat straw), sewage sludge, fungus residue, medicinal residue, and food waste. It has excellent processing capabilities for materials with high moisture content (typically 50%-70%), such as fresh manure from livestock farms, which it can grind smoothly without clogging. For high-fiber materials like straw, pre-cutting can improve grinding results.

What are the advantages of the new vertical grinder over traditional grinders?

The new vertical grinder has significant advantages. Its vertical structure occupies only 1/3 to 1/2 the floor space of traditional horizontal grinders, making it particularly suitable for small and medium-sized organic fertilizer production companies with limited space. In terms of material handling, this type of grinder is highly adaptable to high-humidity and highly viscous materials. Its unique screenless design or large-aperture screen, combined with high-speed rotating components, prevents material blockage and ensures smooth material discharge, a feat difficult for traditional grinders. Furthermore, it boasts high crushing efficiency, resulting in a more uniform particle size after crushing, meeting the stringent fineness requirements of organic fertilizer production.

What common faults can occur with this new vertical grinder during use, and how can they be resolved?

Material blockage: This may be caused by excessive moisture content, excessive feed rate, or foreign matter inside the equipment. Solutions include reducing the moisture content of the material (perhaps by airing it properly or adding dry material to the mix), controlling the feed rate to ensure uniform feed, and shutting down the equipment to clean out foreign matter.

Severe blade wear: This is caused by prolonged use and material friction. Regular inspections should be performed, and blade wear exceeding 1/3 of its original thickness should be promptly replaced.

Abnormal equipment vibration: This may be caused by unbalanced hammer or blade installation, bearing damage, or motor failure. The corrective measures include reinstalling and adjusting the hammer and blade to maintain balance; inspecting the bearings and replacing them if damaged; troubleshooting the motor and repairing or replacing faulty parts.

What are the key maintenance points for new vertical crushers?

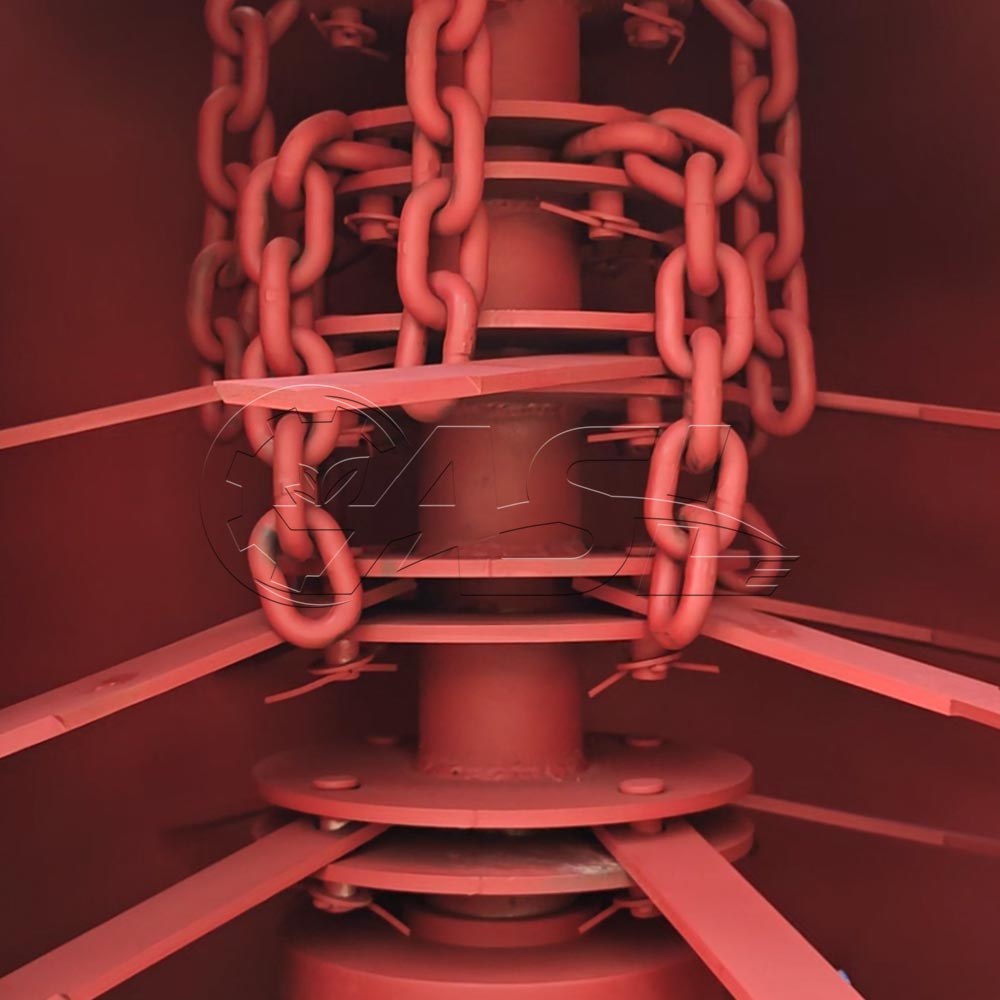

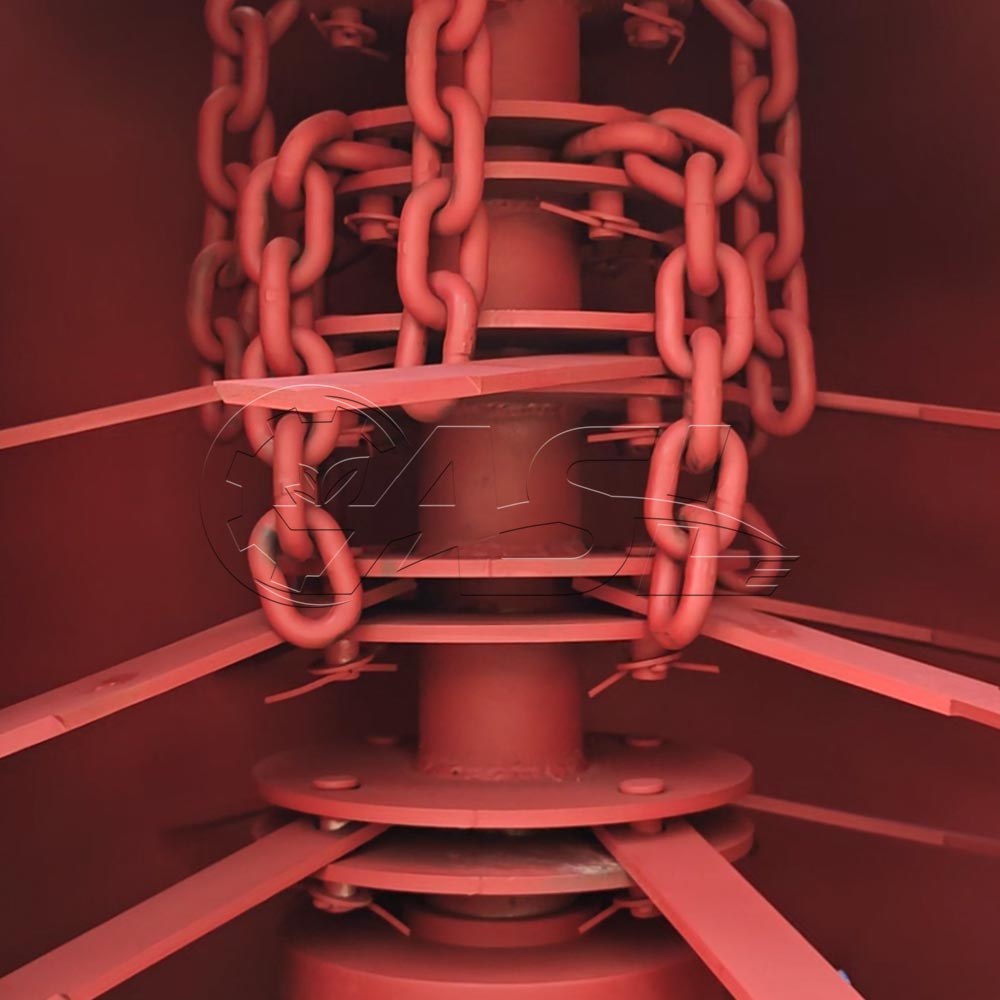

Daily maintenance is crucial and can extend the life of the equipment. For vulnerable parts like chains and blades, clean any material adhering to their surfaces after each operation to prevent it from drying out and affecting the next use. Regularly inspect them for wear and replace severely worn parts promptly. Bearings are critical components and require regular grease (molybdenum disulfide high-temperature grease is recommended). Lubricate them after each use to prevent excessive lubrication and dust absorption. Also, check the belt tension and adjust any belt tension if it's too loose or too tight. Regularly clean the inside and outside of the equipment to remove dust and debris and keep it clean. Additionally, perform a comprehensive inspection of the equipment after every period of operation, checking for loose connections and tightening them promptly.