What materials are primarily screened by a fertilizer drum screening machine? What applications are they suitable for?

Organic fertilizer drum screening machines are used to grade materials throughout the entire organic fertilizer production process. They can process fermented, decomposed organic fertilizer, unfermented raw materials, and finished organic fertilizer granules. Suitable applications include raw material pretreatment in small and medium-sized organic fertilizer plants, removal of impurities (such as rocks, plastic, and uncomposted lumps) after fermentation, and particle size grading of finished organic fertilizer. They can also be used to screen similar materials such as biofertilizer and compound organic fertilizer.

What is the maximum screening efficiency of this equipment? What factors affect it?

The effective screening efficiency of a conventional organic fertilizer drum screening machine can reach 85%-95%, which is specifically affected by three factors:

Material characteristics: moisture content and particle uniformity;

Equipment parameters: drum speed and screen aperture;

Operation method: Whether the feed rate is uniform and whether the screen is cleaned regularly.

Due to the moisture and viscosity of organic fertilizer materials, there is a risk of screen clogging

after long-term use. However, this can be prevented and cleaned in three ways:

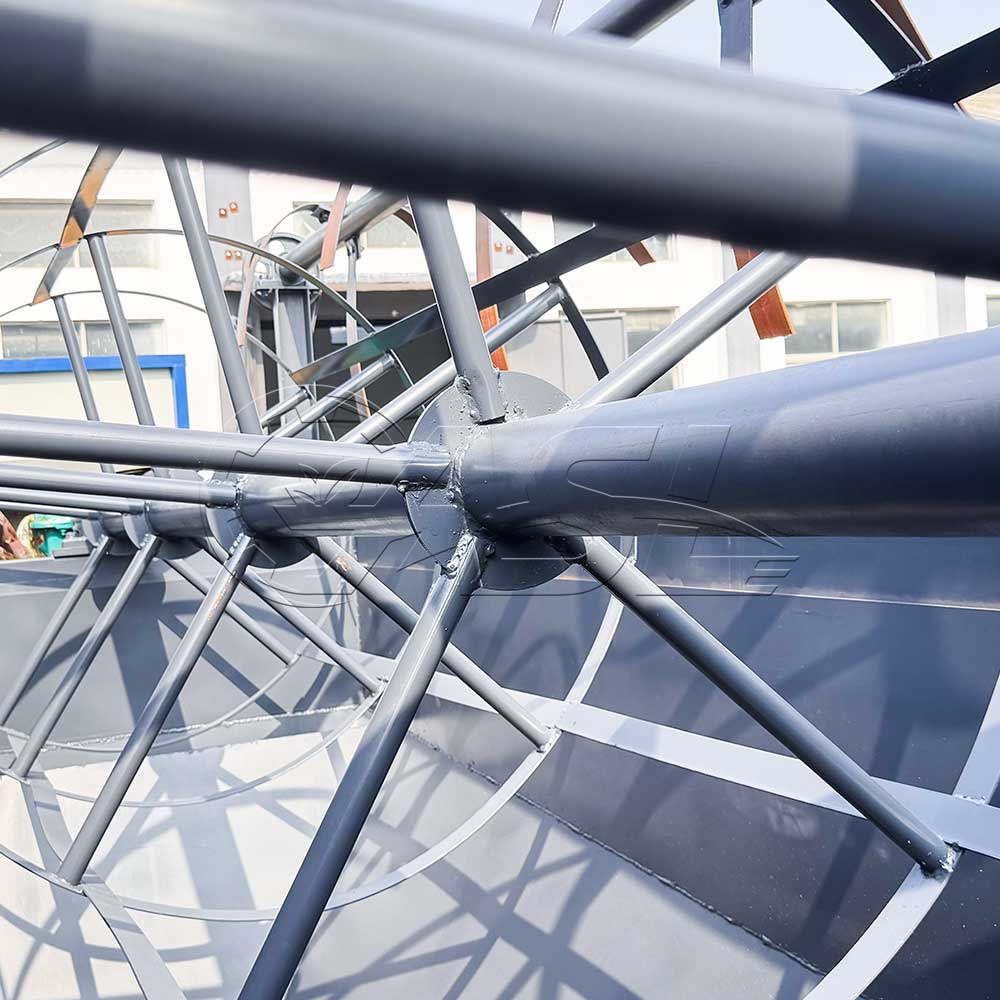

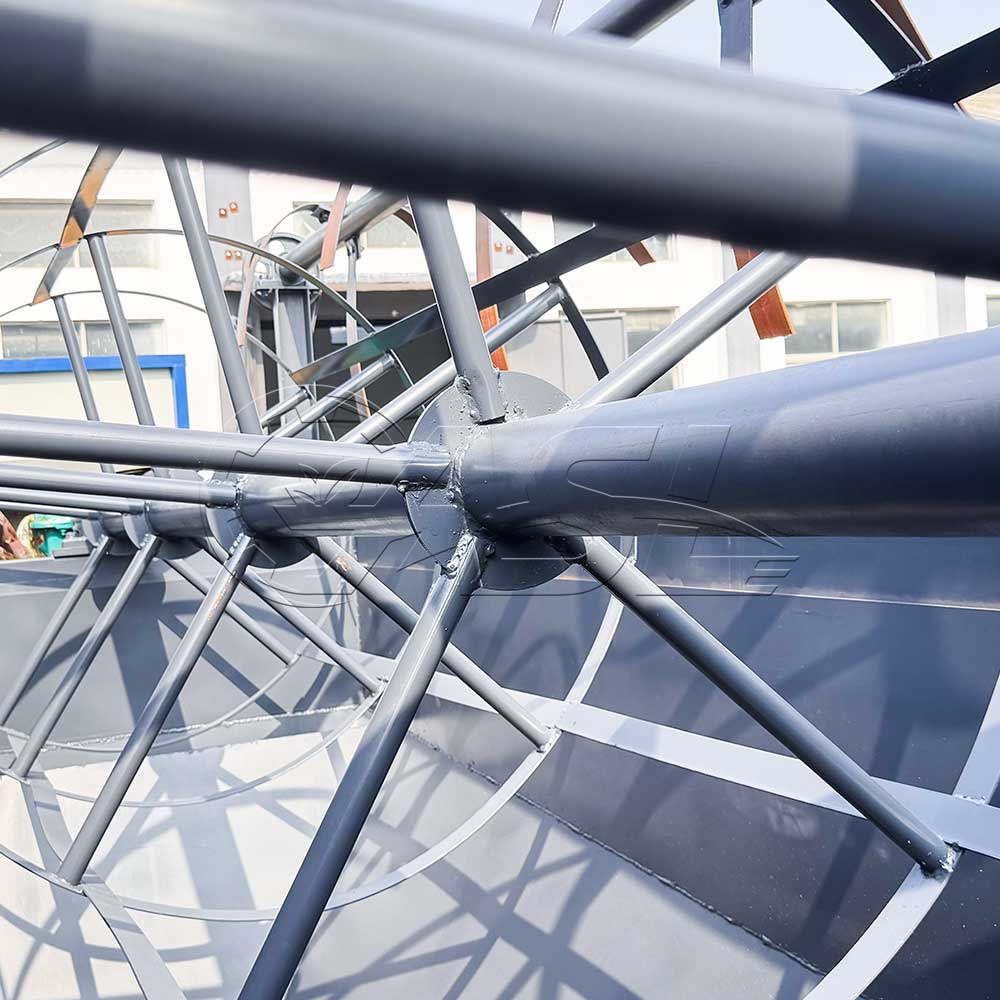

1. Preventive measures: Use a machine with Equipment with "anti-clogging designs" (e.g., cleaning brushes installed inside the drum to automatically clean the screen mesh during operation) should be used to break up large lumps of material before feeding; and the material moisture content should be controlled within a reasonable range.

2. Blockage Cleaning: For minor blockages, the machine's built-in cleaning device (such as a brush or pinball) can be activated, along with reverse airflow for auxiliary cleaning. For severe blockages, the machine should be shut down and then cleaned manually with a high-pressure water jet or a soft-bristled brush to avoid scratching the screen with hard tools.

Is the equipment complex to operate? Does it require specialized technicians?

The equipment is easy to operate and does not require specialized technicians. Ordinary workers can master it after 1-2 hours of training. The core operating steps are just three:

1. Before starting the machine: Check the screen, power supply, and lubrication, and adjust the feed conveyor speed.

2. During operation: Observe the uniformity of the feed. If blockage or uneven screening occurs, adjust the feed rate or activate the cleaning device immediately.

3. After shutdown: Turn off the feed, wait until the material in the drum is completely drained, then shut down the machine and clean any remaining material.