What materials are suitable for processing? Are there any moisture content requirements?

It is suitable for organic fertilizers (such as straw charcoal and composted manure powder), feeds (such as soybean meal and straw powder), and biomass fuels (such as wood chips and straw). The material moisture content should be controlled between 8% and 15%. A moisture content that is too high can easily clog the die holes and soften the pellets, while a moisture content that is too low can increase pelletizing resistance and wear the die and rollers. High-moisture materials require drying first. Dry materials can be tempered by adding a small amount of water or oil.

Can the length and diameter of the pellets be adjusted?

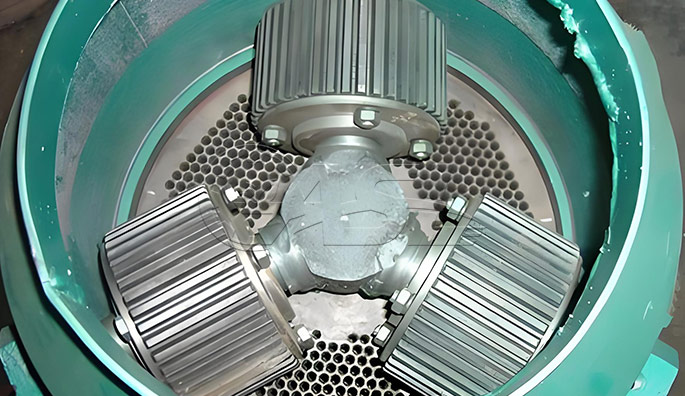

Yes, they can. The pellet diameter is determined by the die hole size, and can be changed by replacing the die with a different hole size. The pellet length is adjusted by adjusting the distance between the cutter and the die or the cutter speed. It can generally be adjusted within a range of 3-15mm, meeting the pellet size requirements for different applications.

What are common operational faults? How can they be resolved?

Common faults include:

① Die hole blockage (due to high moisture content or impurities in the material); this requires stopping the machine to clean the die holes and increasing material screening.

② Insufficient pellet strength (too little pressure); the gap between the press wheel and the die should be adjusted (reducing the gap increases pressure);

③ Abnormal equipment noise (due to bearing wear or loose parts); the bearings should be replaced and the bolts tightened;

④ Motor overload (due to too hard material or excessive feed); the material should be crushed or the feed rate should be reduced.

Is it necessary to add a binder during the pelletizing process?

In most cases, no. Flat die pelletizers rely on strong extrusion, requiring low material viscosity. Even low-viscosity materials (such as sawdust and fly ash) can be pelletized. However, for extremely loose materials (such as lightweight mineral powder), a binder (such as starch or clay) of 1%-3% can be added to improve pellet strength and reduce breakage.