What materials are suitable for processing? What are the raw material requirements?

It is suitable for organic fertilizers (such as fermented livestock and poultry manure and composted straw), inorganic fertilizers (such as compound fertilizers and phosphate fertilizers), metallurgical powders, and ceramic raw materials. Raw materials must meet the following requirements: uniform particle size (recommended ≤2mm), a moisture content of 20%-30% (a higher moisture content will cause caking, while a lower moisture content will make it difficult to form), and no large impurities (such as stones or metal). For organic fertilizer raw materials with high fiber content, they must be crushed in advance to prevent entanglement that affects granulation.

"Is particle size adjustable? How?

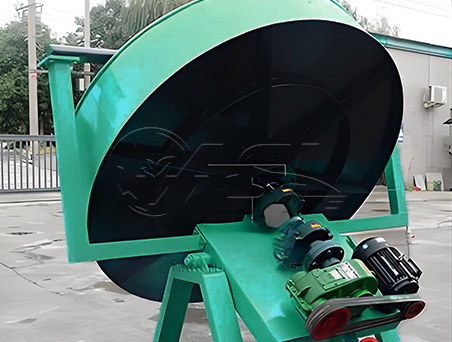

Yes, particle size can be adjusted. Particle size can be controlled primarily by adjusting the disc inclination angle (the larger the inclination, the smaller the particles, typically in the range of 30°-50°), varying the disc speed (the higher the speed, the smaller the particles, typically 15-30 rpm), controlling the material feed rate (excessive feed can lead to oversized and uneven particles), and adjusting the moisture or binder content (increasing the amount promotes particle growth). By adjusting these parameters in combination, particles between 0.5-10mm can be produced. "

"What is the pelletizing efficiency? How many pellets can be produced per hour?

Pelletizing efficiency varies depending on equipment specifications. Small disc pelletizers (1-2 meters in diameter) have an hourly output of 0.5-3 tons, medium-sized equipment (2-3 meters in diameter) 3-10 tons, and large equipment (over 3 meters in diameter) can reach 10-20 tons. Actual efficiency also depends on the characteristics of the raw material. Materials with good fluidity and easy agglomeration (such as decomposed manure) are more efficient, while light, loose materials (such as straw powder) are relatively inefficient. "

"What faults are common during operation, and how can they be resolved?

Common faults include:

① Uneven pellet size (due to unstable feed or improper moisture control). This requires stabilizing the feed rate and precisely adjusting the water spray volume;

② Material sticking to the disc (excessive moisture content or too small disc tilt angle). Reduce the moisture content or increase the tilt angle, and clean the disc promptly;

③ Abnormal equipment vibration (loose anchor bolts or worn bearings). Tighten the bolts or replace the bearings; ④ The motor is overloaded (too much material or stuck), so reduce the feed and check the transmission system.