What is the core working principle of a cyclone dust collector?

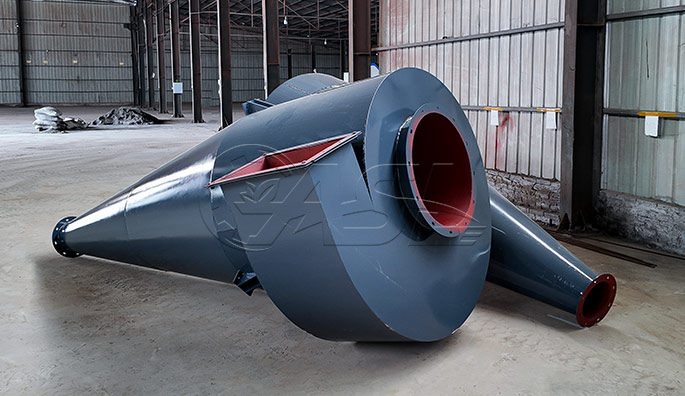

The core principle is centrifugal separation. Dust-laden gas enters the dust collector tangentially, rotating at high speed within the dust collector, generating centrifugal force. This forces dust particles, which are much denser than the gas, toward the walls. The dust then falls along the walls and is discharged into the hopper at the bottom. The purified gas is then discharged through the exhaust pipe at the top of the dust collector.

What is the dust removal efficiency of a cyclone dust collector?

Conventional cyclone dust collectors can achieve 85%-95% efficiency for dust larger than 5-10μm, and over 98% for dust larger than 20μm. However, efficiency for fine powders smaller than 5μm is typically less than 70% (requiring a bag filter or electrostatic precipitator for "secondary purification").

What are the key factors affecting efficiency?

Key factors affecting efficiency:

Inlet air speed: Too low an air speed (<12m/s) results in insufficient centrifugal force and incomplete dust separation. Too high an air speed (>20m/s) causes airflow turbulence and secondary dust entrainment. The optimal air speed is typically 14-18m/s;

Equipment Structure: The smaller the cylinder diameter (greater centrifugal force), the longer the cone height (optimizes the dust drop path), and the appropriate exhaust pipe insertion depth (avoids short-circuiting), the higher the efficiency.

Dust Characteristics: The larger the dust particle size and the higher the density, the higher the efficiency. Sticky dust tends to adhere to the cylinder wall, gradually reducing efficiency.

Does a cyclone dust collector require regular maintenance? What are the key points of daily maintenance?

1. Regular maintenance is required. Improper maintenance can easily lead to reduced efficiency, equipment blockage, and even damage. Daily Maintenance Key Points:

2. Hopper Cleaning: Clean dust accumulated in the hopper promptly to prevent excessive dust "bridging." Blockage or even backflow into the cylinder impacts airflow.

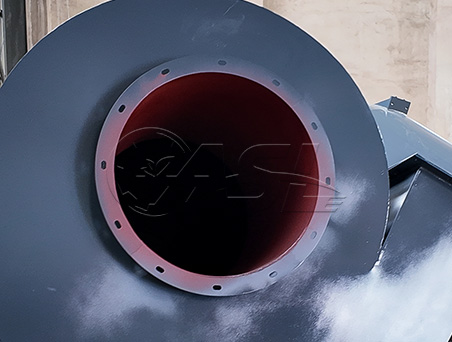

3. Cylinder wall inspection: Open the inspection door and inspect the cylinder wall for dust adhesion. If worn, repair or replace it promptly.

4. Seal inspection: Check the seals of the air inlet, outlet, inspection door, and ash discharge valve. If seals are deteriorating, replace them promptly to prevent air leakage.

Ash discharge valve maintenance: Check the ash discharge valve motor and bearings for proper operation. Regularly add lubricant to ensure smooth ash discharge.