What materials are suitable for the semi-wet material grinder for organic fertilizer?

The semi-wet material grinder is designed for organic materials with a moisture content of 30%-60%. Its core processing targets include livestock and poultry manure (such as chicken, cow, and pig manure), biogas residue, sewage sludge, food waste, medicinal residue, mushroom residue, and mixtures of straw and manure. Due to the high moisture content of these materials, traditional grinders are prone to sticking and clogging. However, the semi-wet material grinder's special structural design allows it to efficiently process these "semi-wet, semi-dry" materials. For example, biogas residue fresh from a biogas digester can be directly fed into the grinder for grinding without the need for additional drying.

What is the key difference between a semi-wet material grinder and a conventional grinder?

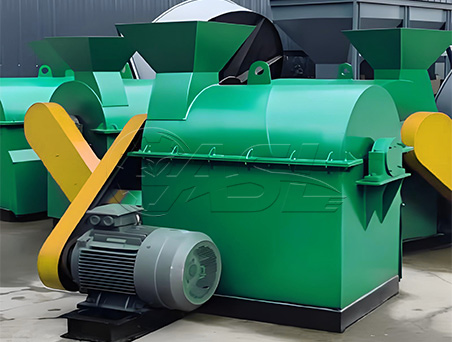

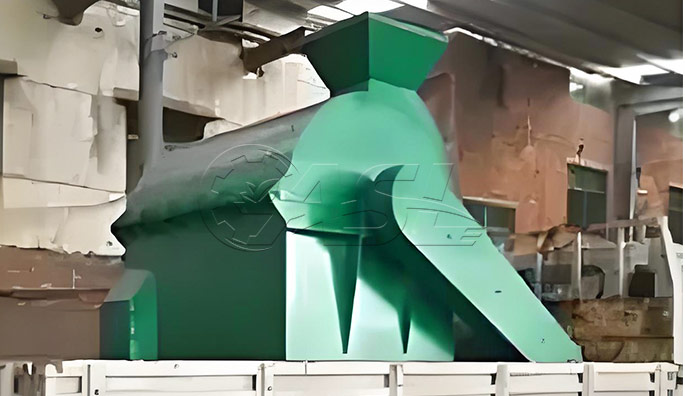

The key difference lies in its ability to handle high-moisture materials. When handling materials with a moisture content exceeding 40%, conventional pulverizers are prone to material adhesion, leading to clogging of the pulverizing chamber and poor discharge. Semi-wet material pulverizers, on the other hand, can crush materials through shearing, squeezing, and tearing, while utilizing the centrifugal force generated by the high-speed rotation of the rotor to reduce material adhesion, ensuring stable operation in high-humidity environments.

How does a semi-wet material pulverizer work?

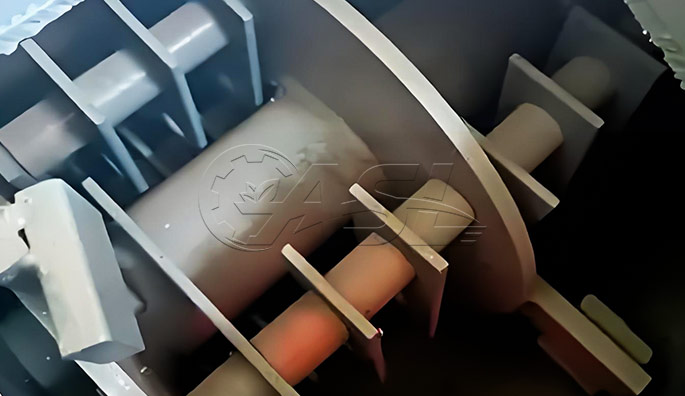

After entering the pulverizing chamber through the feed inlet, the material is initially crushed by the shearing and squeezing action between the high-speed rotating rotor (with blades or claws) and the stationary liner. Subsequently, the centrifugal force of the rotor throws the material toward the inner wall of the pulverizing chamber, where it collides with the liner and teeth, grinding it further into smaller particles. Material that meets the required particle size is discharged through a screen (or the gap in models without a screen), while material that does not meet the required particle size is circulated within the pulverizer until it meets the required particle size. Some twin-shaft models use two counter-rotating rotors that interlock with each other to enhance the tearing effect on sticky materials and reduce the risk of clogging.

What safety precautions should be taken when operating a semi-wet material pulverizer?

① Before feeding, remove metal, stones and other hard objects from the material to avoid damage to the rotor and blades;

② It is strictly forbidden to open the crushing chamber door when the equipment is running to prevent material splashing and injuring people;

③ Before shutting down, stop feeding first and wait until the material in the chamber is emptied before shutting down to avoid excessive load when starting next time;

④ Regularly check safety protection devices (such as emergency stop buttons and protective covers) to ensure sensitivity and effectiveness;

⑤ After handling corrosive materials (such as sludge), clean the equipment in time to prevent parts from rusting.