Chain Crusher

Processing Capacity: 1-15 tons/hour

Motor Power: 11-22kW

Applicable Materials: Livestock and poultry manure, tree branches and sawdust, kitchen waste, garden waste, etc.

Processing Capacity: 1-15 tons/hour

Motor Power: 11-22kW

Applicable Materials: Livestock and poultry manure, tree branches and sawdust, kitchen waste, garden waste, etc.

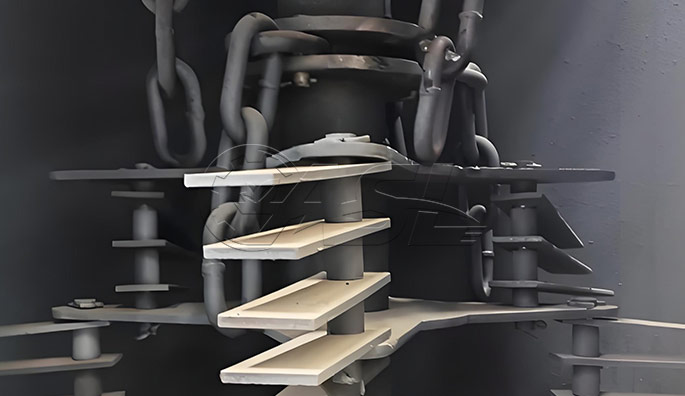

Casing: This is typically a cylindrical or square metal shell with a feed inlet at the top and a discharge outlet at the bottom. Some models are equipped with a screen. The casing must be strong enough to withstand the impact of the material and the rotating chain.

Rotor: The core rotating component, consisting of a main shaft and chain discs fixed to the shaft. Multiple chains are evenly suspended from the chain discs, and the chain length can be adjusted according to the material characteristics.

Chain: The key operating component for crushing. Chain links or hammers can be added to the ends of the chain to enhance the crushing effect. The chain material must be wear-resistant and impact-resistant. Common examples include high-carbon steel and alloy chains.

Drive system: This system consists of a motor, pulleys, or a reducer, driving the rotor at high speed.

Screen: Located above the discharge outlet, the screen is adjusted to different diameters to control the particle size of the crushed material. Substandard material will continue to be crushed within the machine.

Application Areas

1. Organic Fertilizer Production: Crushing livestock and poultry manure, compost, sludge, straw, etc., refining them for pelleting or direct use as bulk organic fertilizer.

2. Biomass Energy Processing: Crushing biomass raw materials such as branches, wood chips, and sugarcane bagasse to provide pre-treatment for biomass pellet fuel and biomass power generation.

3. Waste Disposal: Crushing food waste, garden waste, etc. to reduce volume or enable subsequent resource utilization.

4. Other Applications: Crushing wet materials in the feed industry and processing viscous intermediates in the chemical industry.

The crushing process in a chain pulverizer is primarily based on "impact" and "tearing":

1. Material enters the machine casing through the feed inlet and falls around the rapidly rotating rotor.

2. The rotor drives the chain at high speed, causing the chain to spread radially under centrifugal force, violently colliding with the material entering the crushing chamber.

3. The impact of the chain shatters or tears large or fibrous materials. For sticky materials, the high-speed agitation of the chain breaks down the adhesions between the materials, causing them to disperse and break up.

4. The crushed material moves downward under the action of gravity. If the particle size is smaller than the screen aperture (or meets the requirement without a screen), it is discharged from the discharge port. Material that does not meet the required particle size continues to be repeatedly impacted and sheared by the chain within the chamber until it meets the required particle size.

Advantages of vertical composting tanks:

1. Strong Adaptability:

It is highly effective at crushing high-humidity, high-viscosity, and high-fiber materials, and is less prone to clogging.

2. High Crushing Efficiency:

The "dynamic crushing zone" created by the high-speed chain rotation allows for rapid material processing.

3. Simple Structure:

The core components (chain and rotor) are easily disassembled and assembled. Wear on the chain can be replaced individually, eliminating the need for overall repair, resulting in low maintenance costs.

4. Flexible Particle Size Adjustment:

By changing the screen aperture or adjusting the rotor speed, different particle sizes can be achieved to meet subsequent processing requirements.

5. Relatively Reasonable Energy Consumption:

Compared to hammer mills, chain pulverizers require less effort to crush fibrous materials and have lower specific energy consumption.

Model | Power(KW) | Capacity(t/h) | Feed Grain Size(mm) | Output Particle Size(mm) |

ASLLTF-500 | 11 | 1-3 | <100 | ≤3mm (57%-90%) |

ASLLTF-600 | 15 | 2-5 | <100 | |

ASLLTF-800 | 22 | 5-8 | <120 | |

ASLLTF-800II | 18.5×2 | 10-15 | <150 |

What materials are suitable for chain crushers?

Chain crushers are suitable for crushing a variety of medium-to-low hardness, brittle materials. Suitable materials include coal, coke, ore, fertilizers (granular fertilizers such as ammonium chloride and potassium chloride), slag, and construction waste (brick and tile fragments).

How does a chain crusher work?

The core component of a chain crusher is multiple chains (or links) mounted on a rotor. When the rotor rotates at high speed, the chains spread radially under the action of centrifugal force. After entering the crushing chamber from the feed inlet, the material is repeatedly struck and torn by the high-speed chains. Simultaneously, the materials collide with each other, gradually breaking them down. The crushed material is discharged through the bottom screen (or discharge port) under the action of gravity, while larger particles continue to be crushed within the chamber until they reach the desired particle size.

What are the advantages of a chain crusher compared to a hammer mill?

The advantages of a chain crusher are primarily reflected in its adaptability to materials and its crushing method. Compared to hammer mills, chain mills have a certain degree of elasticity in their chains, providing better impact cushioning against hard objects during the crushing process and making them less susceptible to damage. They are therefore suitable for processing materials with small amounts of impurities. However, their crushing force is relatively gentle, resulting in slightly less uniform particle size than a hammer mill. Furthermore, their chains are prone to wear, making them less efficient at processing hard materials. Furthermore, chain mills have a simpler structure and lower maintenance costs.

What safety precautions should be taken when operating a chain mill?

Operational precautions:

① Before starting the machine, check for foreign objects in the crushing chamber and for loose or broken chains. Ensure all components are functioning properly before restarting.

② While the machine is running, do not open the cover or reach into the crushing chamber to prevent the chain from being thrown out or material from splashing and injuring anyone.

③ Feed the material evenly and continuously to avoid overloading caused by excessive material being fed at once.

④ If the machine makes unusual noises, vibrates violently, or emits smoke, immediately shut down the machine, disconnect the power cord, inspect, and troubleshoot the problem before restarting.

⑤ After operation, wait until the machine has completely stopped before cleaning any remaining material and inspecting the components.

What are the common malfunctions of chain crushers? How can they be resolved?

Chain breakage or wear: This is often caused by long-term processing of hard materials, excessive chain tension, or material fatigue. Solution: Replace worn or broken chains and use high-strength, wear-resistant chains. Adjust the chain tension to the appropriate level to avoid processing hard materials that exceed the machine's capacity.

Screen clog: This may be caused by high material moisture, excessively fine particle size requirements, or a damaged screen. Reduce material humidity, replace a screen with a larger mesh size, clean any blockages, and replace damaged screens promptly.

Motor overheating or overload: This is usually caused by excessive feed, unstable voltage, or damaged motor bearings. Reduce the feed rate, check the power supply voltage, replace damaged bearings, and install an overload protection device if necessary.

Copyright 2025 Henan Nonghuilian Machinery Co., Ltd. Sitemap