Dynamic Automatic Batching System

Capacity: 10-20 tons/hour

Feeding method: Gravity, screw, or belt

Weighing range: 0.4-1.0 tons

Power and gas consumption: 1.0 kW, 0.4-0.6 MPa compressed air, 1 m³/h

Capacity: 10-20 tons/hour

Feeding method: Gravity, screw, or belt

Weighing range: 0.4-1.0 tons

Power and gas consumption: 1.0 kW, 0.4-0.6 MPa compressed air, 1 m³/h

Silos: Multiple silos are used, such as three, four, five, or even more. Each silo is used to store different raw materials, such as nitrogen, phosphorus, and potash fertilizers, organic materials, and additives.

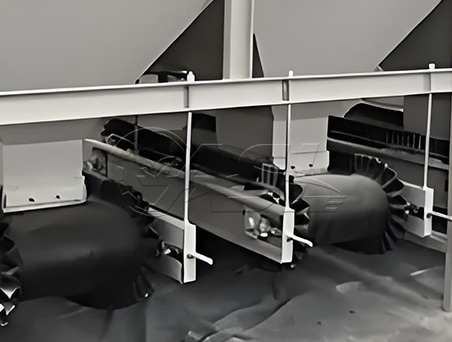

Feeding Devices: Commonly used include belt feeders and screw feeders. Belt feeders consist of a conveyor frame, a skirted endless belt, a motor, a reducer, and a frequency converter; screw feeders convey materials through the rotation of spiral blades.

Weighing Devices: Electronic belt scales or nuclear scales are used as measuring equipment, along with load cells and a scale frame, to accurately weigh materials.

Control System: Typically composed of a PLC or host computer system, operated via a touch screen or wired remote control, capable of setting mix parameters and real-time monitoring and control of the mix process.

Cleaning Devices: Such as scrapers, these devices are used to remove residual material from the belt to ensure proper operation and accurate metering.

Application Areas

1. Organic Fertilizer Production Line: Used to mix and proportion raw materials such as livestock and poultry manure, straw, and sludge, ensuring the stability of the fermentation and granulation processes.

2. Compound Fertilizer Production: Supports precise blending of essential elements such as nitrogen, phosphorus, and potassium to meet the needs of various formulations.

3. BB Fertilizer (Blended Fertilizer) Production: The dynamic batching system enables rapid blending and integrated packaging.

Working principle of Dynamic automatic batching system:

When the organic fertilizer multi-bin dynamic batching machine is in operation, the material enters the equipment and is transported by a conveyor to the weighing area. The weighing sensor measures the material weight in real time and transmits the data to the PLC. The PLC controls the conveyor speed, feed rate, and other parameters according to the preset formula and process requirements to achieve precise batching.

Advantages of a Dynamic automatic batching system:

1. Silos:

Multiple silos are available, such as three, four, five, or even more. Each silo is used to store different raw materials, such as nitrogen, phosphorus, and potash fertilizers, organic materials, and additives.

2. Feeding Device:

Common feeders include belt feeders and screw feeders. Belt feeders consist of a conveyor frame, a skirted endless belt, a motor, a reducer, and a frequency converter; screw feeders convey materials through the rotation of spiral blades.

3. Weighing Device:

Electronic belt scales or nuclear scales are used as measuring equipment, along with load cells and a scale frame, to accurately weigh materials.

4. Control System:

This typically consists of a PLC or host computer system, operated via a touch screen or wired remote control. It allows for setting mix parameters and real-time monitoring and control of the mix process.

5. Cleaning Device:

Such as a cleaning scraper is used to remove residual material from the belt to ensure proper operation and accurate metering.

Model | Yield(t/h) | Quantity of silos(pcs) | Power(kw) | External dimensions(mm) | Single silo flow rate(kg/h) |

ASLDP1200 | 750-1000 | 3-8 | 1.5 | (4000~10500)x1400x2410 | 200-8000 |

ASLDP1500 | 1000-1500 | 3-8 | 1.5 | (4900-12900)x1700x2430 | 200-8000 |

"What is the maximum number of raw materials that a multi-bin dynamic batching machine for organic fertilizer can process simultaneously?

A multi-bin dynamic batching machine typically supports the simultaneous batching of 3-8 raw materials. Smaller machines may have 3-4 silos, suitable for basic formulations with a limited variety of raw materials. Larger multi-bin dynamic batching machines can be equipped with 6-8 silos, capable of meeting complex organic fertilizer formulation requirements. For example, they can precisely mix cow dung, chicken manure, straw powder, nitrogen, phosphorus, potassium compound fertilizers, trace elements, functional microbial agents, and other raw materials simultaneously."

"What forms of organic fertilizer raw materials can this machine process?

It can process a variety of organic fertilizer raw materials, including powder, granules, and small chunks. Powdered raw materials such as composted livestock and poultry manure (crushed into powder or small granules), straw powder, peat moss powder, and peanut shell powder; granular fertilizers such as monoammonium phosphate and potassium sulfate; and small, pre-processed mushroom residue can all be precisely batched using a multi-bin dynamic batching machine. For raw materials prone to agglomeration, the silo is typically equipped with a de-caking device, such as a vibrating motor or pneumatic de-caking device, to prevent caking and blocking the feed opening, ensuring smooth feeding.

Is the equipment complex to operate? Does it require specialized technicians?

The operation is simple, and ordinary workers can master it after simple training. The equipment uses a PLC. The control system or host computer system allows users to set the mixing parameters of various raw materials on the touch screen. Most equipment features automated control. Workers only need to check the equipment status and set the recipe parameters before starting up. Once started, the equipment will automatically complete the mixing process. During operation, the operator is primarily responsible for monitoring the equipment's operating status. If any malfunction or abnormality occurs, the equipment will issue an alarm, which can be easily troubleshooted according to the operating manual. No specialized electrical or mechanical technicians are required to be on duty for a long time.

Can the equipment's mixing speed be adjusted according to production needs? What is the adjustment range?

The mixing speed can be adjusted according to production needs. Generally, the equipment's mixing speed has a wide adjustment range, achieved by adjusting the feed motor speed and the conveyor belt speed. For example, a typical four-bin dynamic batcher, in its standard configuration, has a feed motor speed adjustable from 0 to 1500 rpm and a conveyor belt speed adjustable from 0.1 to 2 m/min. Adjustments can be made within seconds. This means that the batching speed can be flexibly set when processing different raw materials and production requirements. If the production task is urgent and production needs to be increased, the motor speed and belt speed can be appropriately increased to increase the batching speed by 30%-50%. If the raw materials are more difficult to control, the speed can be reduced to ensure batching accuracy, making the batching process smoother and more precise.

Copyright 2025 Henan Nonghuilian Machinery Co., Ltd. Sitemap