What materials are suitable for fermentation processing using a chain-type compost turner for organic fertilizer?

This type of compost turner is suitable for a variety of high-moisture, high-viscosity organic materials, such as livestock and poultry manure (chicken, cow, and pig manure), sewage sludge, sugar mill filter mud, distiller's grains, medicinal residues, and mixtures of straw and manure. Its chain structure effectively conveys and turns these easily agglomerated materials. For example, in sewage treatment plants, it can handle high-moisture sludge and straw mixtures, preventing incomplete turning caused by material adhesion.

What are the structural characteristics of a chain-type compost turner compared to other types of compost turners?

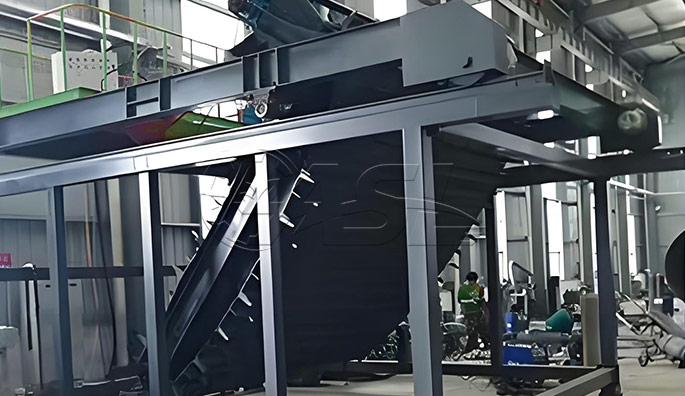

A chain-type compost turner utilizes chains and chain plates as its core transmission and turning components. The chain plates are typically made of high-strength steel and feature specially designed shifting teeth. Compared to wheel-type compost turners, their turning action is smoother, with greater material crushing power, making them suitable for handling sticky materials. Compared to crawler-type compost turners, they are more suitable for continuous operation on fixed tracks, resulting in a more compact overall structure and a relatively small footprint.

Is the operation of a chain-type compost turner complicated? Does it require dedicated personnel?

Chain-type compost turners are relatively easy to operate. Modern machines are often equipped with PLC control systems, enabling automatic or semi-automatic operation. The operator sets parameters such as the chain speed and turning frequency through the control panel, and the machine automatically completes the turning operation. In manual mode, a joystick controls the start, stop, and speed. Generally, workers with minimal training can operate the machine, but to ensure stable operation, it is recommended that a dedicated person be responsible for daily operation and monitoring.

What are the site requirements for chain-type compost turners?

Chain-type compost turners typically operate on pre-set tracks. Therefore, the site must be flat, and the tracks must be securely installed and parallel to avoid equipment stalls caused by uneven tracks. Fermentation material piles must be stacked according to the equipment's turning width and depth specifications. The height should not exceed 1.2 times the equipment's rated turning depth to avoid increasing the equipment's load. Additionally, the site must have a good drainage system to prevent water accumulation from impacting equipment operation and material fermentation.