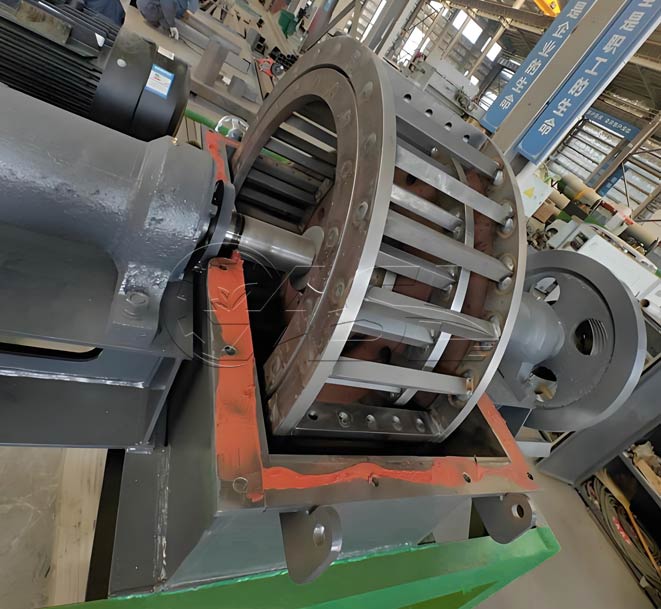

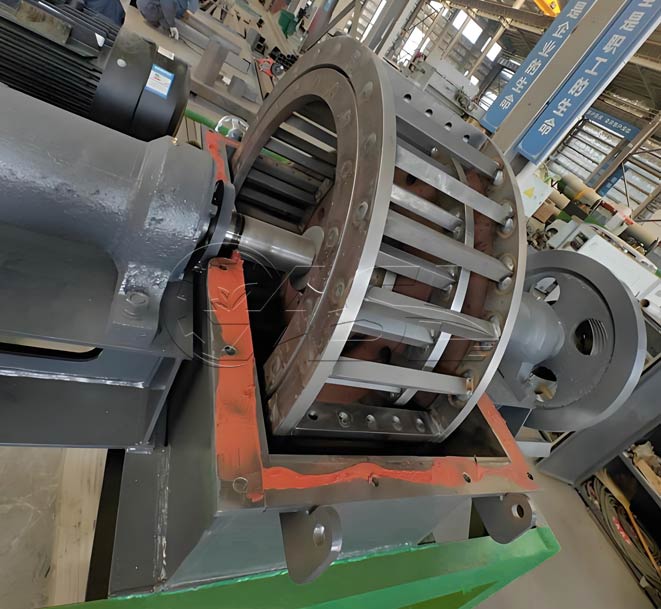

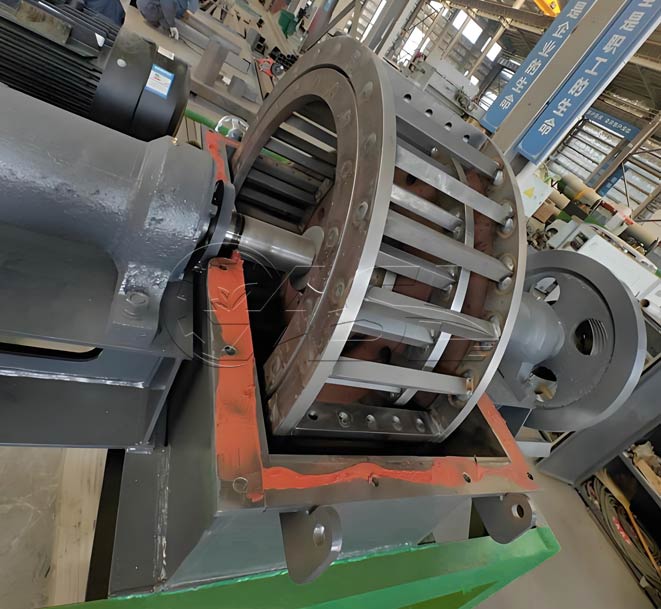

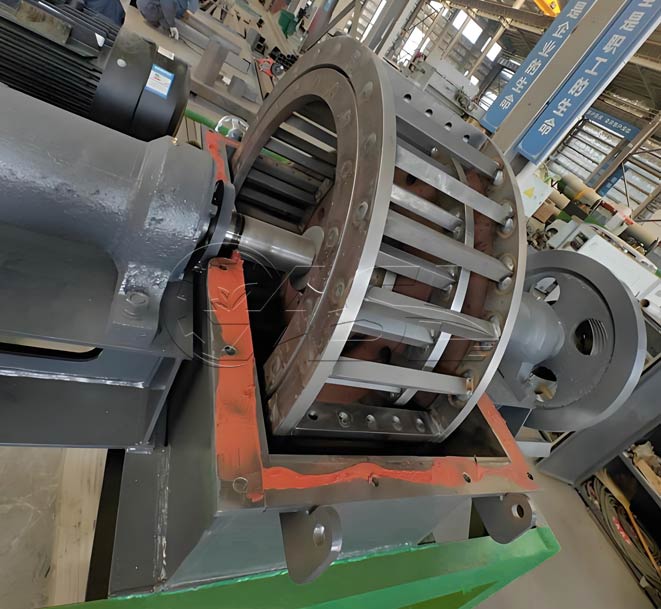

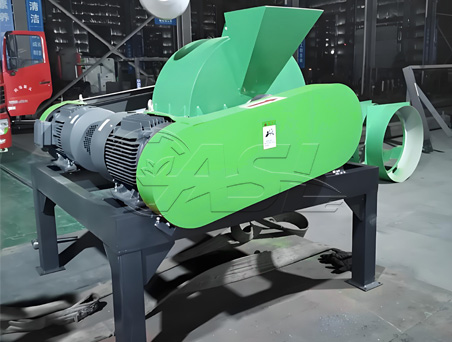

Cage Crusher

Processing capacity: 2-8 tons/hour

Motor power: 5.5-18.5kW

Discharge particle size: 0.3-0.5mm

Applicable materials: Granular urea, agglomerated urea, crystallized urea, agglomerated fertilizer, etc.

Processing capacity: 2-8 tons/hour

Motor power: 5.5-18.5kW

Discharge particle size: 0.3-0.5mm

Applicable materials: Granular urea, agglomerated urea, crystallized urea, agglomerated fertilizer, etc.

Feed system: This includes the feed hopper and feed adjustment device, which controls the speed and flow of material entering the crushing chamber to prevent equipment overload due to excessive feeding.

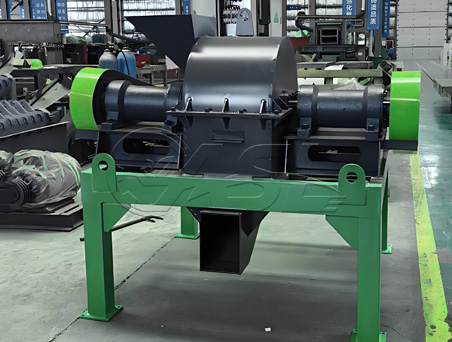

Crushing Chamber: The core working area of the equipment, housing two sets of counter-rotating cages.

①Inner Cage: Consists of a central shaft, steel discs, and multiple concentrically arranged rings of impact rollers (bars). It typically rotates clockwise at high speed. The impact rollers are made of high-carbon steel or wear-resistant alloy, reaching a hardness of HRC 50-60.

②Outer Cage: Fits over the inner cage. Its structure is similar to the inner cage, but it has more impact rollers and is more densely arranged. It typically rotates counterclockwise, creating a counter-shear force against the inner cage.

Screen: Located at the bottom of the crushing chamber, screens of varying apertures are selected based on the desired particle size, providing grading and discharge control.

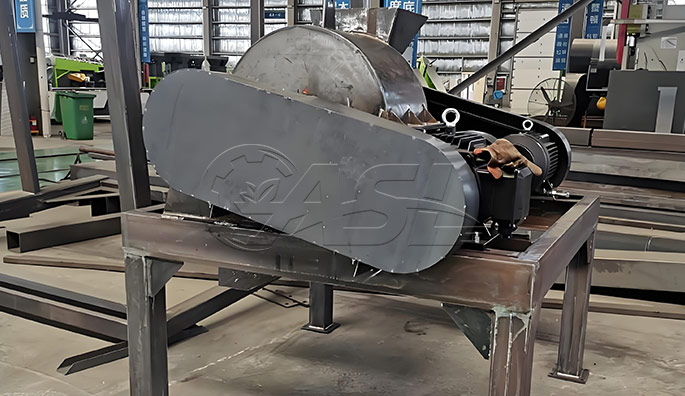

Drive System: Consists of an electric motor, pulleys, and drive shafts, powering the twin-cage rotors. The speed is typically 1000 rpm.

Frame and Casing: The frame supports the entire equipment. The casing is welded from thick steel plates and lined with a wear-resistant lining to reduce wear and noise.

Application Areas

1. Organic Fertilizer Production: Crush organic waste such as crop straw, livestock and poultry manure, and manure into fine particles for easy application to farmland, improving soil fertility.

2. Feed Processing: Suitable for fine grinding of fish meal and conventional livestock and poultry feed production, it can grind materials to the appropriate particle size to meet feed production requirements.

3. Grain Processing: It can be used in processes such as wheat milling to grind grain into flour of varying particle sizes to meet diverse food processing needs.

4. Other Applications: It can also be used in the glass industry, for fine and coarse grinding of brittle and soft materials. It also has certain applications in the crushing of traditional Chinese medicine slices.

The cage mill's pulverizing process is based on a "multi-stage impact-shear" mechanism. The detailed process is as follows:

1. Material enters the pulverizing chamber from the feed hopper and first falls into the center of the inner cage (small rotor). There, it is impacted by the high-speed rotating inner cage rollers, initially crushing the material into small particles.

2. Under the action of centrifugal force, the initially crushed material moves outward and enters the gap between the inner and outer cages. As the inner and outer cages rotate in opposite directions, the material is subjected to repeated impact, shearing, and rubbing by the two sets of rollers, further reducing its size.

3. When the material particle size is smaller than the screen aperture, it passes through the screen under the action of gravity and airflow and is discharged from the discharge port. Coarse particles that do not meet the required particle size remain in the pulverizing chamber and continue to be crushed by the rollers until they meet the required particle size.

4. Throughout the entire process, the material is gradually crushed by multiple rounds of rollers, resulting in a more uniform particle size distribution. Furthermore, due to the short contact time between the rollers and the material, overheating is less likely to occur, making it suitable for pulverizing heat-sensitive materials.

Cage mill product advantages:

1. High crushing precision:

Adjustable fineness, high screen aperture precision, narrow particle size distribution, and smooth particle surface make it suitable for applications requiring high particle size precision.

2. Wide material adaptability:

It can process materials with a moisture content of 8%-15%, and is well suited for powders with medium to low hardness and small particles.

3. High production efficiency:

The cage rotor structure increases crushing efficiency by 40%, resulting in high energy utilization and a higher throughput than a hammer mill at the same power.

Model | Power(kw) | Capacity(t/h) | Inlet Size(mm) | Dimensions(mm) |

ASLLSF-600 | 11×2 | 4-6 | 300×250 | 1500×1400×1500 |

ASLLFF-800 | 15×2 | 6-10 | 380×320 | 1500×1500×1500 |

Can it process materials with high moisture content? What is the maximum moisture content limit?

This equipment is suitable for processing materials with a moisture content of 8%-15%, such as straw and distiller's grains. If the moisture content exceeds 15%, the material may stick to the screen and clog the discharge port. We recommend pre-treating the material to reduce the moisture content before grinding.

What are the advantages of a cage mill compared to a hammer mill?

Compared to a hammer mill, the advantages of a cage mill are:

① More uniform particle size with less variation;

② Lower energy consumption for medium- and low-hardness materials.

What are the wearing parts? What is the replacement cycle and cost?

The main wearing parts are the impact roller (cage bars) and the screen. The impact roller is made of wear-resistant alloy and has a lifespan of approximately 1,000-2,000 hours; the screen has a lifespan of approximately 500-800 hours. The cost of replacing a single set of beater rollers is approximately 2,000-5,000 yuan, and the cost of replacing the screen is approximately 500-1,000 yuan, depending on the equipment model and material.

Is the equipment difficult to maintain? What regular maintenance is required?

The maintenance level is moderate. Regular maintenance includes:

① Check the cage bars for tightness and replace loose parts every 500 hours of operation;

② Clean the screen monthly to prevent clogging;

③ Check the drive belt tension and replenish bearing lubricant every six months. Under normal operating conditions, the annual maintenance cost is approximately 8,000-15,000 yuan.

Copyright 2025 Henan Nonghuilian Machinery Co., Ltd. Sitemap