How does the organic fertilizer rotary drum granulator combine the advantages of a drum and teeth?

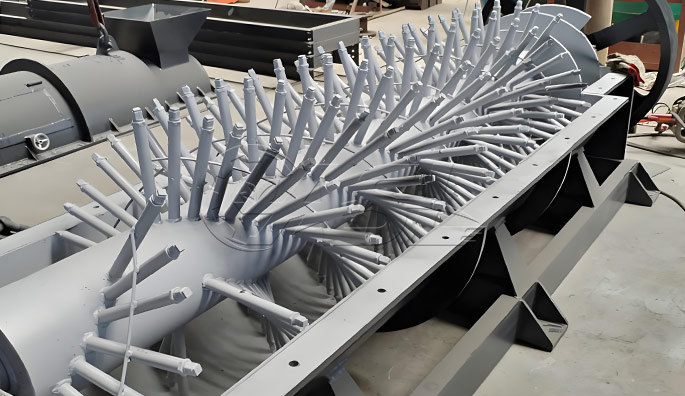

This device combines the "rolling agglomeration" of a drum granulator with the "powerful mixing" of a tooth granulator. Features. The tilted rotating drum causes the material to tumble overall, while the high-speed internal agitator teeth shear, break up, and squeeze the material. This dual action accelerates the agglomeration of fine particles. The drum provides a macroscopic space for particle formation, while the agitator teeth enhance local mixing and bonding. This is particularly suitable for organic raw materials with low viscosity or high fiber content, ensuring particle uniformity while improving granulation efficiency.

What is its core advantage compared to simple drum granulators or agitator teeth granulators?

The core advantage lies in its wider adaptability: For low-viscosity raw materials (such as composted straw), the mechanical force of the agitator teeth can compensate for insufficient bonding; for high-fiber materials, the gentle tumbling of the drum reduces fiber entanglement and prevents localized clumping. Furthermore, the granulation rate is higher (typically ≥92%), and the particle strength is intermediate between the two. By combining the low energy consumption of the drum with the rapid granulation of the agitator teeth, overall production efficiency is improved. 10%-20%.

How can particle size and shape be controlled? Can multiple specifications be achieved simultaneously?

Particle size can be adjusted in three ways: drum speed, agitator speed, and material moisture content. The shape is primarily near-spherical, with a sphericity ≥0.8. If multiple specifications are required, a grading screen can be installed after discharge. By replacing the screen mesh, different particle sizes can be separated without frequent adjustments to equipment parameters.

What are the key points of daily maintenance? Which components require frequent inspection?

Daily maintenance should cover both the drum and agitator: ① Daily check the agitator wear (for deformation or nicks) and remove entangled fiber impurities; ② Weekly check the lubrication of the drum support bearings and replenish high-temperature grease; ③ Monthly calibrate the drum tilt angle (to prevent vibration-induced deviation) and check the drive belt tension. Consumable parts include the agitator teeth (made of high-chromium cast iron, which is wear-resistant but requires regular replacement), the drum lining (replaced every 1-2 years), and the spray system nozzles (to prevent clogging).