What organic fertilizer raw materials is this equipment suitable for?

It is suitable for a variety of organic fertilizer raw materials, including livestock and poultry manure (such as chicken manure, cow manure, and pig manure), composted straw, fermented food waste, biogas residue, mushroom residue, and other harmlessly treated and composted organic materials. However, it is important to keep the moisture content of the raw materials within 30%-40%, and impurities (such as rocks and metal) must be removed in advance to avoid affecting the granulation effect and equipment life.

Can the particle size after granulation be adjusted?

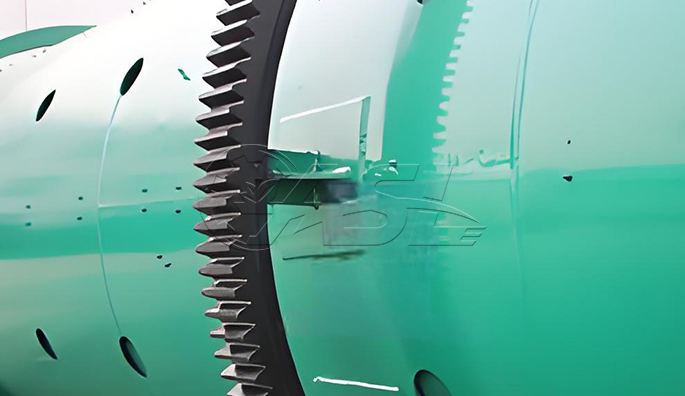

Yes, it can be adjusted. Particle size is primarily controlled by adjusting the drum speed, inclination angle, material moisture content, and the amount of added binder. Generally speaking, faster drum speeds and larger inclination angles result in smaller particles. Appropriately increasing the moisture content or adding binder can increase particle size. Some equipment can also optimize particle size by replacing the internal lifter structure to meet different user requirements.

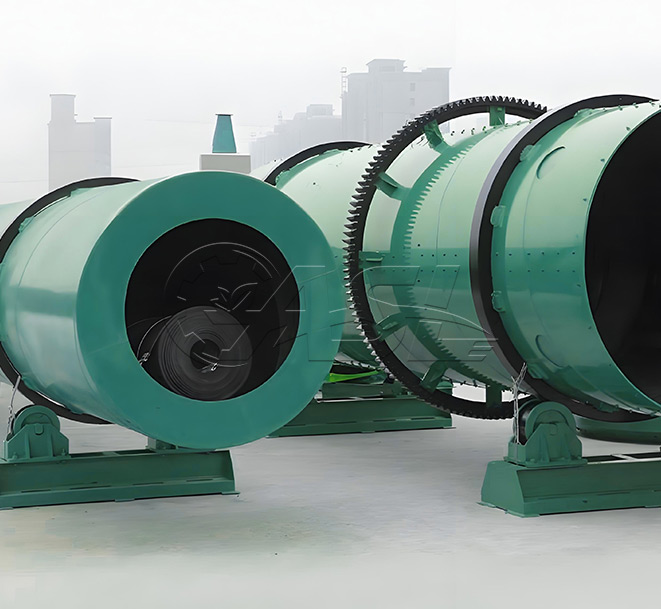

What is the production efficiency of the equipment? How many pellets can be produced per hour?

Production efficiency varies depending on the equipment model, raw material characteristics, and pellet size. A small rotary drum granulator can produce approximately The capacity of a granulator is 1-5 tons, with medium-sized equipment reaching 5-20 tons. Granulators used in large production lines can produce over 20 tons per hour. Actual production capacity also depends on factors such as the maturity and fluidity of the raw materials. Fully decomposed raw materials with few impurities significantly improve granulation efficiency.

Is energy consumption high during operation? Is it energy-efficient and environmentally friendly?

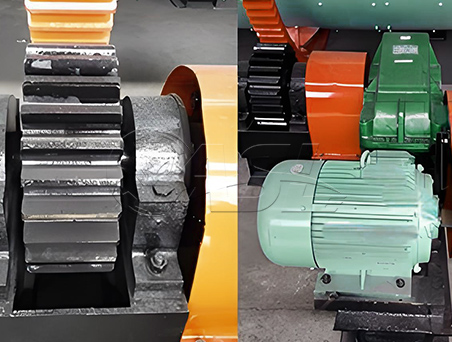

Compared to other methods, such as extrusion granulation, rotary drum granulators consume less energy. Their primary power comes from the motor that drives the drum, and energy consumption is proportional to the size of the equipment (e.g., a 10-ton/hour machine consumes approximately 15-22 kilowatts). Furthermore, the equipment produces no exhaust gas or wastewater during operation and converts waste organic matter into high-quality fertilizer, thus embracing energy conservation and environmental protection.