What industries and materials is the inclined screen solid-liquid separator primarily suitable for?

Due to its efficient separation properties, the inclined screen solid-liquid separator is widely used in livestock farming, slaughtering and processing, food processing, printing and dyeing, chemical industry, municipal wastewater, aquaculture, and other fields. Specific suitable materials include: farm manure (pig manure, cow manure, chicken manure, etc.), a mixture of blood and meat residue from slaughterhouses, fruit and vegetable juice extraction residue from food factories, printing and dyeing wastewater scum, solid-containing wastewater from the chemical industry, and screen residue from municipal wastewater pretreatment. It is particularly suitable for treating suspended materials with a solids content of 1%-15% and a particle size ≥0.1mm.

What is the device's solid-liquid separation efficiency? What is the approximate moisture content of the solid residue and liquid after separation?

Under normal operating conditions, the inclined screen solid-liquid separator can achieve a solid-liquid separation efficiency of 85%-95% (depending on material characteristics and equipment parameters). After separation, the moisture content of the solid residue is typically controlled at 65%-80%, resulting in a loose, loose solids that can be directly used for composting, organic fertilizer production, or incineration. The solids content of the separated liquid can be reduced to below 1%, reducing the load on subsequent wastewater treatment systems (such as biogas tanks and aeration tanks) and improving overall treatment efficiency.

How should the equipment's processing capacity be selected? What factors should be considered when determining the model?

The processing capacity should be determined based on three key factors: the average daily total volume of solid-liquid mixture in actual production, the maximum hourly processing peak, and the solids concentration of the material. Common equipment capacities range from 1-5 m³/h (small) to 50-100 m³/h (large). Varies. When selecting a model, you should also consider: the hardness of the solid particles in the material, their corrosiveness, the presence of fibrous impurities, and the separation requirements of subsequent processing steps (such as the moisture content of the solid residue and the clarity of the liquid).

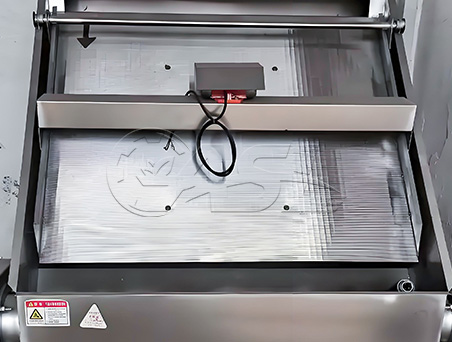

Is the screen a consumable part? What is its service life? Is it easy to replace?

The screen is the core consumable component of an inclined screen solid-liquid separator. Its service life is directly related to the material characteristics, frequency of use, and maintenance methods. For low-hardness materials such as livestock manure, a standard stainless steel screen (pore size 0.3-1mm) has a service life of approximately 3-6 months. For materials containing hard particles (such as sand and gravel), a wear-resistant alloy screen should be selected, extending its service life to 6-12 months.

The equipment is typically designed with a "quick-release screen structure." Replacement requires no disassembly of the entire machine; simply loosen the bolts on both sides, remove the old screen, and replace it with a new one. This can be completed by one person in 15-30 minutes, making it highly convenient for maintenance.