What types of organic fertilizer raw materials are suitable for this granulator?

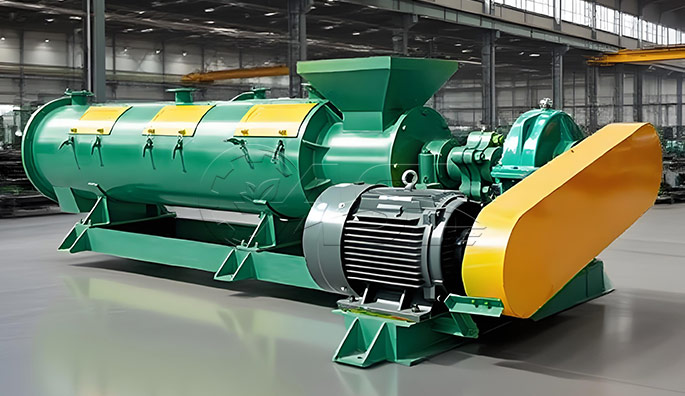

The organic fertilizer agitator granulator is highly adaptable to a wide range of raw materials. Fermented livestock manure, such as chicken, cow, and sheep manure, is a common suitable raw material. Because it contains a certain amount of stickiness, it is easily formed by the agitator. Powdered crop straw, as well as agricultural waste such as distiller's grains and mushroom residue, can also be processed. However, for these lightweight, high-fiber materials, process parameters may need to be adjusted or other materials may need to be added to ensure effective granulation. Furthermore, sludge from municipal sewage treatment plants, after dehydration and harmless treatment, can also be processed into organic fertilizer granules using the agitator granulator.

What is the quality of the granules produced by the agitator granulator? Do the granules meet the requirements for strength and shape?

The granules produced by the agitator granulator are of relatively good quality. Under normal circumstances, the granules can achieve a compressive strength of 10-20 Newtons per granule, which is sufficient to meet the strength requirements for storage, transportation, and agricultural use, and is not prone to breakage. The granules produced are nearly spherical, with a sphericity typically ≥0.7. The particle size is generally adjustable between 0.3 and 3 mm, and the granulation rate is high, typically ≥90%. By properly adjusting the material mixing ratio, agitator speed, and internal equipment parameters, the granule quality can be further optimized, ensuring uniform, rounded granules that meet the shape and strength requirements of different users for organic fertilizer granules.

What is the production capacity of the equipment? Can it meet large-scale production needs?

Organic fertilizer agitator granulators come in various sizes. Small-sized equipment has an hourly output of approximately 1-3 tons, suitable for small farms, planting cooperatives, or organic fertilizer production companies with smaller initial investments, meeting fertilizer needs in surrounding areas. Medium-sized equipment generally has an output of 3-6 tons/hour, capable of providing a stable supply of organic fertilizer to medium-sized agricultural production areas. Large-sized equipment can reach an hourly output of 6-10 tons or even higher, and can be used with large-scale automated production lines to achieve large-scale industrial production, meeting the high demand for organic fertilizer in large agricultural bases and agricultural supply markets.

What are the equipment maintenance cycles and key points?

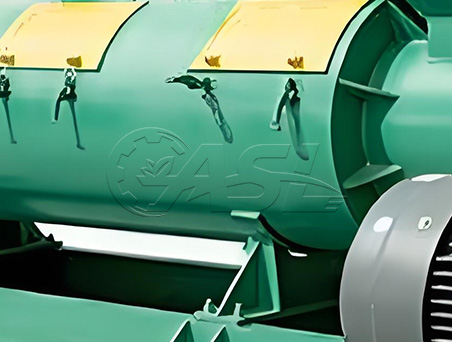

Daily Maintenance: After the equipment has finished operating, clean any remaining material from the surface and interior of the equipment to prevent material accumulation and corrosion. Check all bolts at the connections for looseness and tighten them immediately. Check the operating conditions of the motor and transmission for any abnormal noise, vibration, or overheating.

Weekly Maintenance: Relubricate the equipment's lubrication points, such as bearings and chains, by adding an appropriate amount of lubricant or grease to reduce wear on mechanical components. Inspect the wear of the agitator teeth, record the wear, and estimate the replacement cycle. Clean the equipment's ventilation and heat dissipation components to ensure proper heat dissipation and prevent damage to the motor and other components due to overheating.

Monthly Maintenance: Thoroughly inspect the equipment's electrical system, including ensuring that wiring connections are secure and that the controller is functioning properly. Adjust the tension of the drive belt to ensure stable power transmission. If the equipment is used in harsh environments, perform a deep cleaning monthly to remove accumulated dust and dirt.