What materials is this equipment suitable for? Are there any moisture content requirements?

It is suitable for a variety of dry powder or low-moisture materials, including organic fertilizers (such as composted manure powder and straw charcoal powder), inorganic fertilizers (such as urea and monoammonium phosphate), feed ingredients, and mining dust. The moisture content of the material must be strictly controlled between 8% and 15%. A moisture content that is too high can easily cause the rollers to stick and pellets to clump, while a moisture content that is too low can make pellets difficult to form. The moisture content must be adjusted through drying or conditioning based on the material's characteristics.

Can the shape and size of the pellets be flexibly adjusted?

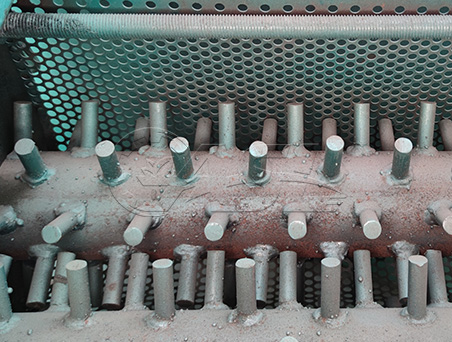

Yes, the pellet shape is determined by the die holes on the roller surface. Common shapes include cylindrical, oblate, and square. The shape can be changed by replacing rollers of different sizes. The pellet size can be adjusted by selecting rollers with different hole diameters (usually 1/4"). 0.5-10mm) and adjusting the screens of the crushing and screening equipment to meet the particle size requirements of different industries.

"Is it necessary to add a binder during the production process?

Generally, no binder is required. Double-roll extrusion granulation relies on the material's inherent plasticity or intermolecular attraction to form the pellets, making it particularly suitable for materials with a certain degree of viscosity (such as humus in organic fertilizer). However, for extremely difficult-to-form materials (such as quartz sand), a small amount of natural binders such as starch or bentonite can be added (usually ≤5%) to improve the pelletizing rate.

"What are common operational faults? How can they be prevented and resolved?

Common faults include: ① Roller sticking (due to excessive moisture content or high material viscosity); humidity should be reduced and the rolls should be cleaned regularly; ② Insufficient pellet strength (too little pressure); the inter-roller pressure should be increased; ③ Abnormal equipment vibration (due to bearing wear or material impurities); bearing replacement and enhanced raw material screening are required; ④ Motor overload (excessive load); feed rate adjustment or drive system inspection.